Why Waterproof Round Seals Are Essential in Industrial Applications

Why Waterproof Round Seals Are Essential in Industrial Applications

Table of Contents

- Introduction to Waterproof Round Seals

- Understanding the Function of Seals in Industry

- Types of Waterproof Round Seals

- Benefits of Using Waterproof Round Seals

- Applications of Waterproof Round Seals in Industries

- Selecting the Right Materials for Waterproof Seals

- Best Practices for Installing Waterproof Round Seals

- Maintenance and Care for Waterproof Seals

- Conclusion

- FAQs

Introduction to Waterproof Round Seals

Waterproof round seals are a pivotal component in the design and functionality of industrial machinery. These seals are engineered to prevent the ingress of water and other contaminants, thereby ensuring operational efficiency and longevity. In the industrial sector, where equipment is often exposed to harsh conditions, the use of waterproof round seals cannot be overstated.

Understanding the Function of Seals in Industry

Seals are critical in maintaining the integrity of mechanical systems. They serve as barriers that prevent leaks, protect components from contamination, and reduce wear and tear. The functionality of seals can greatly influence the performance and reliability of industrial machines, making it essential for engineers and decision-makers to choose the right type of seal for their specific applications.

The Importance of Sealing Technology

Sealing technology plays a vital role in preventing fluid loss and ensuring that moving parts operate smoothly. In industries where machinery operates under extreme conditions, the right seals contribute to increased productivity, reduced downtime, and enhanced safety.

Types of Waterproof Round Seals

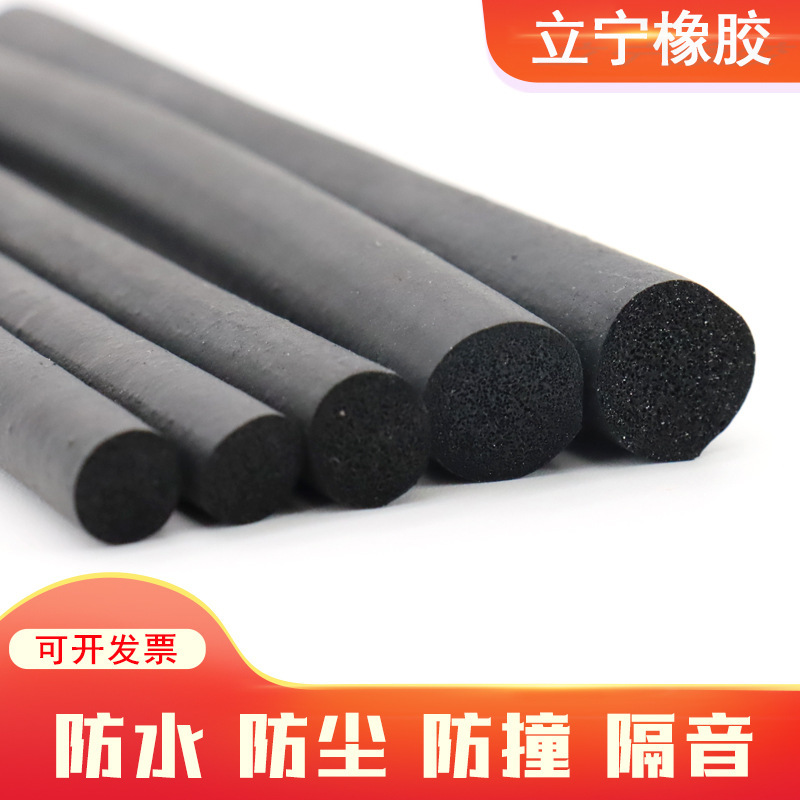

Waterproof round seals come in various designs and materials, each tailored for specific industrial applications. Understanding the different types is crucial for selecting the right seal for your needs.

O-Rings

O-rings are one of the most common types of round seals used in various applications. Their circular shape allows them to compress and create a tight seal between two surfaces, effectively preventing leaks.

Gaskets

Gaskets, while not always round, are often used in conjunction with round seals. They help in sealing joints and can be critical in applications where fluid containment is paramount.

Custom Seals

For specialized applications, custom waterproof round seals can be designed and manufactured to meet specific dimensional and material requirements, ensuring optimal performance.

Benefits of Using Waterproof Round Seals

The incorporation of waterproof round seals in industrial applications brings forth numerous advantages.

Enhanced Equipment Longevity

By preventing water and contaminants from entering machinery components, waterproof round seals significantly extend the lifespan of equipment.

Operational Efficiency

Seals play a crucial role in maintaining the optimal functioning of machines. They ensure that lubricants remain in place, promoting smoother operation and reducing friction.

Safety and Risk Mitigation

Water ingress can lead to hazardous situations, including electrical failures and mechanical malfunctions. Waterproof round seals mitigate these risks by providing a reliable barrier against moisture.

Applications of Waterproof Round Seals in Industries

Waterproof round seals find applications across various sectors, each benefiting from their unique protective qualities.

Automotive Industry

In the automotive sector, waterproof round seals are critical in components such as engines, transmissions, and wheel assemblies, where they help prevent fluid leaks and protect sensitive parts.

Aerospace Applications

In aerospace engineering, the reliability of waterproof seals is paramount. They are used in fuel systems, hydraulic systems, and environmental control systems to ensure optimal performance under extreme conditions.

Manufacturing and Heavy Machinery

Heavy machinery used in construction and manufacturing often operates in wet and abrasive environments. Waterproof round seals help protect these machines from the elements, reducing maintenance costs.

Selecting the Right Materials for Waterproof Seals

Choosing the right material is crucial for the effectiveness of waterproof round seals. Various materials offer different levels of resistance to chemicals, temperatures, and physical wear.

Rubber Seals

Rubber is a popular choice due to its flexibility and resilience. Different types of rubber, such as nitrile or silicone, can be selected based on the specific application requirements.

PTFE Seals

Polytetrafluoroethylene (PTFE) is known for its chemical resistance and low friction properties, making it suitable for high-performance applications.

Metal Seals

In extreme conditions, metal seals may be required. These seals provide excellent durability and can withstand high pressures and temperatures.

Best Practices for Installing Waterproof Round Seals

The proper installation of waterproof round seals is essential for ensuring their effectiveness. Here are some best practices to follow:

Surface Preparation

Clean the surfaces where the seals will be installed. Remove any debris, dirt, or old seal material to ensure a proper fit.

Correct Sizing

Ensure that the selected seal is the correct size for the application. An oversized or undersized seal can lead to leaks.

Avoiding Over-Tightening

When installing seals, avoid over-tightening fasteners, as this can damage the seal and diminish its effectiveness.

Maintenance and Care for Waterproof Seals

Regular maintenance is crucial for the longevity of waterproof round seals. Implementing a proactive maintenance routine can prevent potential issues and costly repairs.

Inspection Routines

Conduct routine inspections to check for signs of wear, damage, or deterioration. Early detection can save time and resources.

Environmental Considerations

Be mindful of the environment in which the seals operate. Exposure to extreme temperatures or aggressive chemicals can impact their performance.

Conclusion

Waterproof round seals are indispensable in industrial applications, ensuring machinery operates efficiently, safely, and reliably. Their ability to prevent water ingress and protect components from contaminants underscores their importance across various industries. By understanding the types, benefits, applications, and maintenance of these seals, engineers and decision-makers can make informed choices that enhance operational performance and equipment longevity.

FAQs

1. What materials are best for waterproof round seals?

The best materials for waterproof round seals include rubber, PTFE, and metal, depending on the specific application requirements and environmental conditions.

2. How do I know if my seals need replacement?

Signs of wear, such as leaks, cracks, or deformities in the seal, indicate that it may need replacement.

3. Can waterproof round seals be reused?

In general, it is advisable to replace waterproof round seals rather than reuse them, as reusing can compromise their effectiveness.

4. What industries commonly use waterproof round seals?

Waterproof round seals are commonly used in the automotive, aerospace, manufacturing, and construction industries.

5. How can I maintain my waterproof seals?

Regularly inspect seals for damage, ensure proper installation, and protect them from extreme environmental conditions for optimal maintenance.

Previous:

Related News

Contact Us

Telephone:

Address:Wang Shigong Village, Liyuan Tun Town, Wei County, Xingtai City, Hebei Province