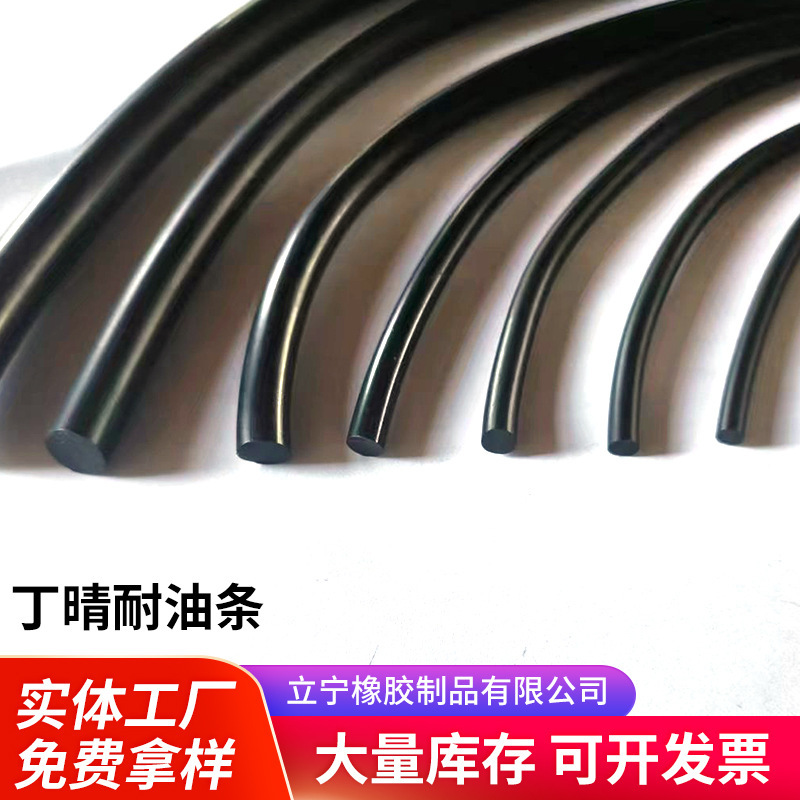

Understanding Black Solid Round O-Type Sealing Strips for Industrial Applications

Black solid round O-type sealing strips are integral components in a variety of industrial applications, particularly in the realm of sealing materials and seals. These strips are designed to provide effective sealing solutions for various equipment, ensuring durability and reliability in demanding environments.

One of the primary functions of black solid round O-type sealing strips is to prevent leakage of fluids or gases. Their circular shape allows for uniform pressure distribution, which enhances their sealing capabilities. This design is particularly effective in applications involving hydraulic systems, pneumatic systems, and other equipment where maintaining pressure is crucial.

Material composition plays a significant role in the performance of these sealing strips. Typically, they are made from elastomers such as nitrile rubber, neoprene, or silicone. Each of these materials offers distinct advantages. For instance, nitrile rubber is known for its excellent resistance to oil and fuel, making it suitable for automotive and machinery applications. Neoprene, on the other hand, provides good resilience and is resistant to weathering, which makes it ideal for outdoor applications. Silicone sealing strips are renowned for their ability to withstand extreme temperatures, ensuring performance in high-heat environments.

The installation of black solid round O-type sealing strips is relatively straightforward, which contributes to their popularity. They can be fitted into grooves or channels in machinery or equipment, and their flexibility allows for easy manipulation during installation. This ease of application not only saves time but also reduces labor costs, making them an efficient choice for manufacturers.

Moreover, these sealing strips are available in various sizes and thicknesses to accommodate different sealing needs. When selecting a sealing strip, it is important to consider factors such as the operating temperature, medium being sealed, and the specific dimensions required for optimal fit. Ensuring the right selection is crucial for achieving effective sealing and preventing operational disruptions.

In summary, black solid round O-type sealing strips offer a robust solution for industrial sealing requirements. Their unique design, coupled with the right material choice, ensures they can effectively handle a range of applications while providing long-lasting performance. Understanding the characteristics and appropriate uses of these sealing strips can enhance operational efficiency in various industries, making them an invaluable component in the world of industrial equipment and components.

Tag:One of the primary functions of black solid round O-type sealing strips is to prevent leakage of fluids or gases. Their circular shape allows for uniform pressure distribution, which enhances their sealing capabilities. This design is particularly effective in applications involving hydraulic systems, pneumatic systems, and other equipment where maintaining pressure is crucial.

Material composition plays a significant role in the performance of these sealing strips. Typically, they are made from elastomers such as nitrile rubber, neoprene, or silicone. Each of these materials offers distinct advantages. For instance, nitrile rubber is known for its excellent resistance to oil and fuel, making it suitable for automotive and machinery applications. Neoprene, on the other hand, provides good resilience and is resistant to weathering, which makes it ideal for outdoor applications. Silicone sealing strips are renowned for their ability to withstand extreme temperatures, ensuring performance in high-heat environments.

The installation of black solid round O-type sealing strips is relatively straightforward, which contributes to their popularity. They can be fitted into grooves or channels in machinery or equipment, and their flexibility allows for easy manipulation during installation. This ease of application not only saves time but also reduces labor costs, making them an efficient choice for manufacturers.

Moreover, these sealing strips are available in various sizes and thicknesses to accommodate different sealing needs. When selecting a sealing strip, it is important to consider factors such as the operating temperature, medium being sealed, and the specific dimensions required for optimal fit. Ensuring the right selection is crucial for achieving effective sealing and preventing operational disruptions.

In summary, black solid round O-type sealing strips offer a robust solution for industrial sealing requirements. Their unique design, coupled with the right material choice, ensures they can effectively handle a range of applications while providing long-lasting performance. Understanding the characteristics and appropriate uses of these sealing strips can enhance operational efficiency in various industries, making them an invaluable component in the world of industrial equipment and components.

Related News

Contact Us

Telephone:

Address:Wang Shigong Village, Liyuan Tun Town, Wei County, Xingtai City, Hebei Province