EPDM Foam: The Ultimate Solution for Industrial Sealing Needs

EPDM foam has emerged as a cornerstone in the realm of industrial sealing solutions. With its exceptional performance and versatility, EPDM (Ethylene Propylene Diene Monomer) foam provides an unparalleled sealing capability that is crucial for a wide range of industrial applications. In this article, we will delve deep into the properties, advantages, applications, and maintenance of EPDM foam, showcasing why it stands out among other sealing materials in the industry.

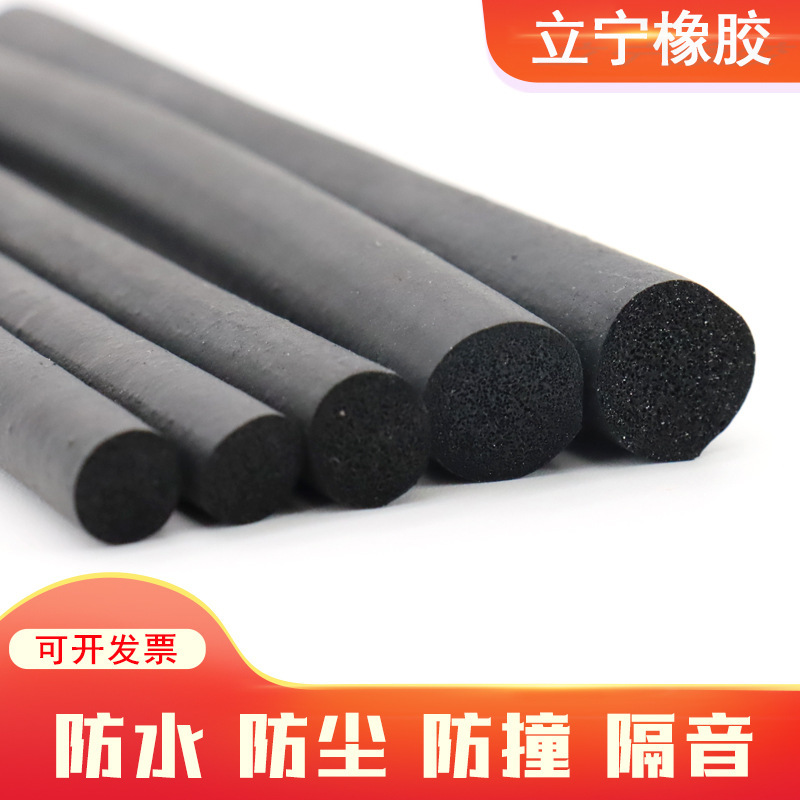

EPDM foam is a synthetic rubber material formulated from ethylene, propylene, and diene monomers. This combination gives EPDM foam its unique characteristics, allowing it to withstand extreme weather conditions, chemicals, and oxidative agents. Generally available in various densities and thicknesses, EPDM foam can be tailored to meet specific sealing needs across diverse industrial sectors.

The chemical composition of EPDM foam includes ethylene (approximately 45-75%), propylene (approximately 25-55%), and a small percentage of diene monomer, which helps enhance its cross-linking properties. This composition endows EPDM foam with flexibility, durability, and excellent resistance to environmental factors.

This type of foam shows remarkable resistance to a wide range of chemicals, including acids, alkalis, and salts. Such properties make EPDM foam suitable for use in chemical processing plants and other harsh environments.

EPDM foam maintains its integrity under high temperatures, making it an excellent choice for applications requiring thermal resistance. It can function effectively in temperatures ranging from -40°F to 240°F (-40°C to 116°C).

Compared to other sealing materials, EPDM foam offers a cost-effective solution without compromising on quality and performance. Its durability reduces the need for frequent replacements, saving costs in the long run.

EPDM foam can be utilized in various industries, including automotive, construction, HVAC, and manufacturing. Its adaptability makes it suitable for a wide range of sealing requirements.

In the automotive sector, EPDM foam is used for weather stripping, seals around windows and doors, and gaskets in engines. Its ability to withstand high temperatures and weather conditions makes it ideal for protecting vehicle interiors.

In building and construction, EPDM foam is commonly used for sealing gaps and joints in roofs, windows, and doors to prevent water infiltration and improve energy efficiency.

For enhanced adhesion, apply a compatible adhesive to the back of the foam and the surface where it will be installed. Allow the adhesive to become tacky before pressing the foam into place.

In conclusion, EPDM foam stands out as the ultimate solution for industrial sealing needs due to its unique properties, versatility, and cost-effectiveness. Its ability to resist environmental factors, chemicals, and extreme temperatures makes it an invaluable asset across various industries. Whether in automotive, construction, HVAC, or manufacturing, EPDM foam provides reliable, long-lasting seals that enhance operational performance and efficiency. By choosing EPDM foam, businesses can invest in a sealing solution that not only meets but exceeds their industrial sealing requirements.

Related News

Contact Us

Telephone:

Address:Wang Shigong Village, Liyuan Tun Town, Wei County, Xingtai City, Hebei Province